LAB SCALE HIGH-TECH BIOREACTORS

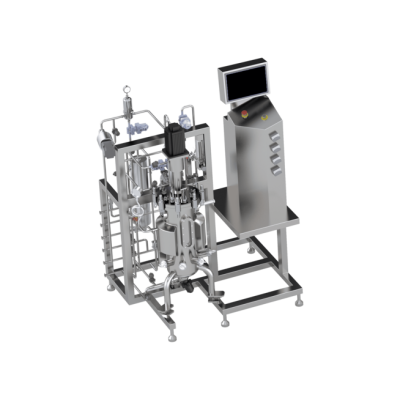

BENCHTOP FERMENTERS AND BIOREACTORS

Bench-top systems for bacteria, yeasts, mammalian cells, and microalgae. Industrial-grade control (Siemens S7 + BIOWIT), autoclavable glass or 316L stainless vessels, and parallel options (TWIN up to multi-line).

LAB SCALE HIGH-TECH BIOREACTORS

BENEFITS

Tailor-made manufacturing

Integrated stainless steel workshop. Great flexibility

PLC SIEMENS S7. Software easily modifiable on request.

European or US critical components: good maintainability

Short delivery times

Installed and maintained by Blanc-Labo

A very wide range: from 5 to 5000L, multi-stage, parallel, bacteria, animal cells, plant cells, algae, mechanical or magnetic stirring…

LAB SCALE HIGH-TECH BIOREACTORS

THE RANGE

Model | Typical working volume | Vessel | Agitation | Sterilization |

Glass–Cells | 0.2–3 L | Glass | Low-shear | Autoclave |

Glass–Bacteria | 0.5–3 L | Glass | Overhead (Rushton/Marine) | Autoclave |

Glass–Algae (Photo) | 0.5–3 L | Glass | Magnetic/overhead | Autoclave |

Steel–Lab | 0.5–3 L | 316L | Bottom-drive | In-situ/Autoclave (per model) |

TWIN | 2×0.5–2×3 L | Glass/316L | Per line | Autoclave/In-situ |

Multiple | 2–10 lines. Up to 5L. | 316L | Per line | Autoclave |

Multiple | 4–24 lines. Up to 10L. | Glass | Per line | Autoclave |

LAB SCALE HIGH-TECH BIOREACTORS

PHOTOS

CONSTRUCTION DETAILS

TECHNOLOGY

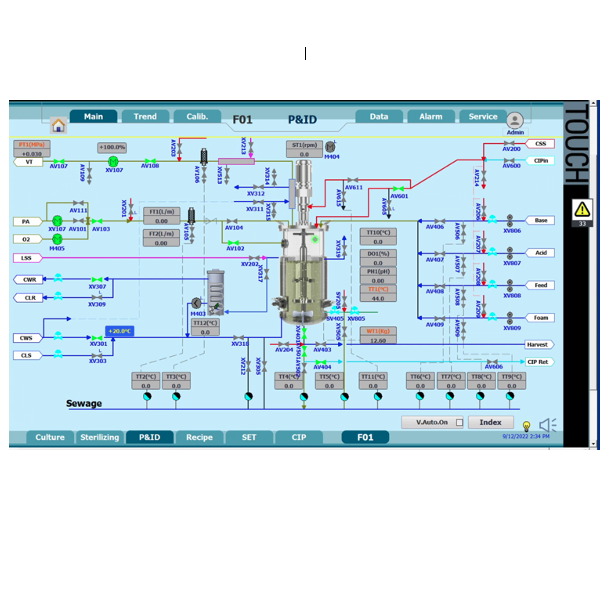

Your pilot fermenter has a dedicated control unit on which are grouped the pumps, mass-flows, and the control screen.

It is made entirely of stainless steel by Bailun Technology in their integrated workshop. This allows us to adapt very quickly to your needs.

The fermenter is equipped with sensors and actuators from mostly Western brands, in order to facilitate its development and maintenance over time in France and Switzerland.

It is mounted on a "skid" at the factory, which is FAT tested before shipment. When it arrives at your site, simply connect it to the utilities to start commissioning.

It is a stable and universal PLC, suitable for a variety of automation applications, especially for manufacturing process control. It is easy to network; it is the control unit of your fermenter.

You can therefore either display on the 10'' touch screen present on the unit all the information present in the software, or on a remote computer (option not encrypted in this offer): transmission of process data, visualization of the process, recorded samples, process parameters, etc...

And also benefit from all the standard peripherals offered by Siemens to integrate your fermenter into an internal industrial network.

The Siemens PLC allows in particular to exchange data in Profinet or in OPC-UA with a SCADA type supervisor.

Control stack: Built on Siemens S7 + FORCE CONTROL for robust, long-term scalability.

Hardware-agnostic: Works with actuators/sensors from multiple brands; easy to evolve as needs change.

Interface: Ergonomic SCADA-style synoptic; software in English (French optional).

Operation modes: Manual or recipe-driven; controls rotameters, pumps, agitation, aeration, heating/cooling from sensor inputs.

Control logic: PID or continuous; cascade strategies supported.

Core features: User/password management, sensor calibration, live synoptic views, alarms, and batch data logging/export.

Automation: Semi-automation via configurable cascading laws.

Your fermenter is fitted with Watson-Marlow peristaltic pumps, selected to match the required flow range for each vessel size. Pumps can run manually or be software-controlled.

Standard setup

4 pumps: acid, base, antifoam, feed.

Expandable

Add channels for online analysis, continuous processing, turbidostat operation, or other process needs.

Standard setup: One rotameter per gas line (air / O₂ / CO₂ / N₂).

MFCs: One or more European-made Mass Flow Controllers—typically Bürkert or Vögtlin—for precise, recipe-driven gas delivery.

Sterility: Gas lines are sterile; filters and valves are in-line sterilizable (SIP).

Control logic: Software supports DO (pO₂)-linked cascades and automatic transitions per your rules.

Aeration rate: vvm (vessel volumes per minute) set to your specification and logged.

Model selection: The exact MFC model is finalized with you after order during the detail-definition phase (same price across options).

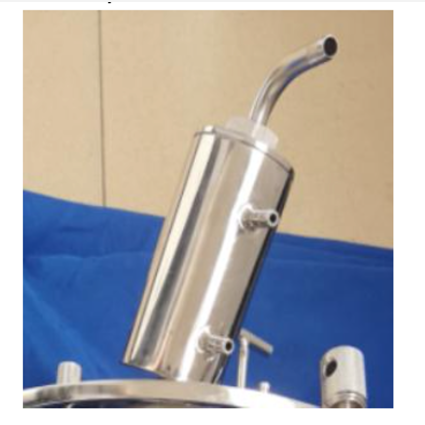

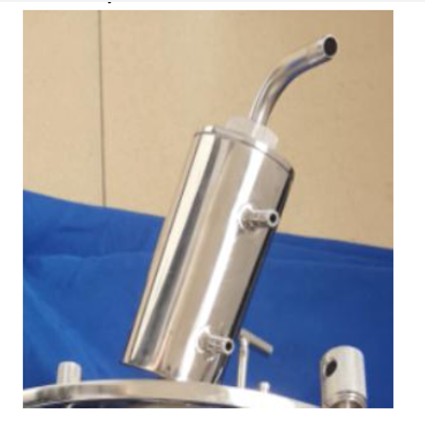

Condenser on exhaust: Positioned on the fermenter outlet to manage vapor and protect downstream components.

In-line sterilizable HEPA filter: Exhaust passes through a SIP-capable HEPA filter; integrity is verified in situ.

Software-controlled relief valve: Provides over/under-pressure protection with setpoints managed by the control system.

Hygienic design: Condenser geometry minimizes liquid hold-up and prevents bacterial buildup.

Condensate drain: Dedicated drain valve, manually operated.

Instrument: GXH-3011N by HUAYUN Instruments; multiple versions available to match application needs.

Placement: Enclosed analyzer box mounted next to the fermenter for continuous online exhaust monitoring.

Measurement principle: NDIR (non-dispersive infrared). Selective absorption at specific IR wavelengths; signal is proportional to target-gas concentration.

Supported gases: Continuous measurement of CO, CO₂, CH₄, NO, SO₂, NH₃ (and variants per model).

Use cases: Suitable for industrial process control (petrochemical, chemical, metallurgy) and research settings (agriculture, healthcare, universities).

RQ Measurement (option)

Add RQ analysis software plus a dedicated PC for continuous RQ calculation.

Note: RQ computation runs on the PC, not on the Siemens PLC.

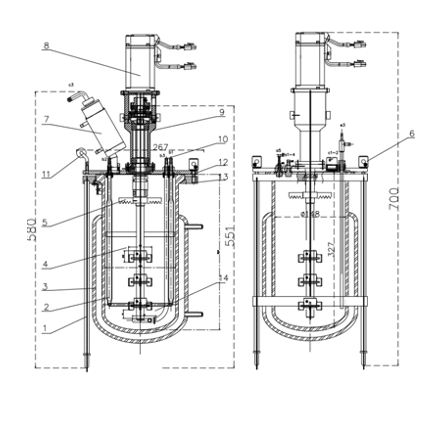

Materials: Product-contact 316L stainless steel tank and lid; 304 stainless steel double jacket; all process piping in 316L.

Sight window: Vertical rectangular viewing window integrated on the tank side.

Jacket rating: Double jacket rated to 3 bar maximum pressure.

Overpressure protection: Fermenter fitted with a safety valve calibrated to your application.

Material: 316L stainless steel.

Standard ports (total: 20):

3 liquid-addition ports

1 motor shaft port

1 inoculation port

1 sterile sampling port

1 harvest/collection port

5 utility/auxiliary connection ports

8 probe/sensor ports

The attached image is illustrative only.

Customization & approval

Port diameters and positions are finalized on a drawing within 7 days of your order and approved before manufacturing starts.

Drive options: Standard top-mounted motor; bottom-drive or magnetic stirring available on request.

Speed range: 50–700 rpm (±0.5%); higher ranges configurable upon request.

Shaft & seal: Rigid drive shaft designed to resist long-term deformation. Mechanical seal typically John Crane (USA).

Impellers: Full set available (e.g., Rushton, marine/axial, etc.) with custom positioning along the drive shaft to match process needs.

Baffles: 4 removable baffles supplied as standard.

Standard: supplied with a ring sparger.

Options: alternative sparger geometries can be selected during the final specification phase to match your process needs.

Sensor: Pt100 temperature probe.

Heating control: Via the double jacket using an electric resistance in the control unit or a steam valve (model-dependent).

Cooling: By mains water or a recirculating loop using an optional chiller/cryostat.

Control range: From mains water temp +5 °C up to 65 °C, accuracy ±0.2 °C.

Display range: 0–150 °C, resolution/accuracy ±0.1 °C.

Sensor: Swiss-made pO₂ electrode.

Control use: DO setpoint drives cascade actions across agitation (rpm), feed, and airflow/O₂ (if configured), plus other parameters.

Range & accuracy: 0–150% DO, accuracy ±3%.

Sequencing: Supports recipe-based DO control with time-based steps (≥ 10 programmable steps).

Sensor: Swiss-made pH electrode (sterilizable).

Control: Stable signal with intelligent PID for high-accuracy regulation; fully integrated in recipe control.

Display range: 0.00–14.00 with ±0.01 resolution.

Auto control range: 2.00–12.00 with ±0.02 control accuracy.

Operation: Online measurement with automatic alarms (out-of-range, fault).

Cabling: pH electrodes and leads made in Switzerland.

Function: Detects foam level in the vessel and automatically triggers the antifoam dosing pump.

Integration: Setpoint, delay, and dosing volume are managed in the control software and logged per batch.

Override: Manual dosing and sensor bypass available from the HMI (for setup or troubleshooting).

20 WEEKS BETWEEN THE NEED AND THE SOLUTION

THE PROCESS | Tailor-Made Manufacturing

Our lab-scale stainless-steel fermenters are built to your specifications. All stainless parts – tanks, lids, and piping – are fabricated by Bailun in an integrated sheet-metal workshop for fast iteration and consistent quality.

Control & integration

Siemens S7 PLC with Bailun-developed software.

Native connectivity to existing supervision systems via OPC-UA and PROFINET (SCADA-type).

Remote monitoring and control from a PC across all your fermenters.

Serviceability

Critical components (e.g., pumps, probes, actuators) are sourced primarily from European or US manufacturers to simplify maintenance, calibration, and long-term parts availability.

We document your process needs. If you have a URS, we use it; otherwise, your answers in our online configurator are enough to start.

We issue an initial technical/commercial estimate based on the URS or configurator input.

Joint review of needs, scope, and options; alignment on constraints and priorities.

One or more passes to finalize the technical scope and commercial terms.

We register your purchase order and deposit to lock timeline and resources.

Formation of a client–installer–manufacturer working group. Objective: validate GA drawings, nozzle/port list, I/O list, and the P&ID before fabrication.

Stainless-steel fabrication, assembly, wiring, software configuration, and internal QA.

Witnessed tests at the factory per agreed protocol; punch-list closure before shipment.

Sea or air freight arranged with packing lists, manuals, and certificates.

On-site installation and utilities hookup, commissioning, operator training, and Site Acceptance Test (SAT) to hand over a ready-to-run system.

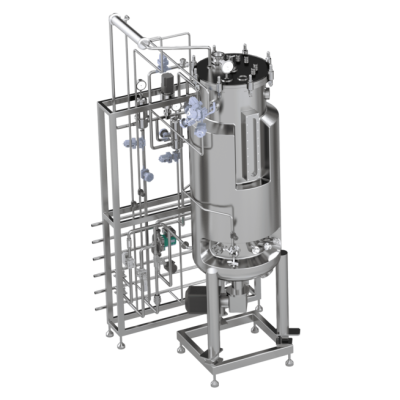

STAINLESS STEEL PILOT SCALE FERMENTERS

PILOT SCALE

BIOREACTORS

Fermenters and bioreactors for the pilot phase, in stainless steel, from 5 to 5000L. Entirely made-to-measure on the basis of a proven components base.

Installing and maintaining fermenters since 2019

PRODUCTION SCALE

BIOREACTORS

Benchtop fermenters and bioreactors Completely tailor-made based on a proven component base. Our fermenters are manufactured by Bailun Technology, a fermenter manufacturer based north of Shanghai.

TALK WITH A SPECIALIST AND GET YOUR QUOTE

NEXT STEPS:

- Tell us your organism, working volume, and strategy.

- We propose configuration, scope, and timeline.

WHY BLANC-LABO

Operational in 20 weeks. Moving forward safely even on a tight budget.

- Fixed deadline: clear milestones and go-live in 20 weeks.

- Turnkey: selection → design → manufacturing → IQ/OQ → start-up with your recipes.

- Industrial control: Siemens S7 PLC + BIOWIT, alarms, data logging and OPC-UA.

- Real scaling: same logic from lab to pilot and industrial (0.2 L → 50,000 L).

- Local support: installation, training, maintenance and spare parts in the UK.

- Defined cost and scope: closed proposal by configuration, no surprises.

- For your process: bacteria, yeasts, cells, microalgae; batch, fed-batch or perfusion.

- Complete documentation: URS, port lists, P&ID (NDA), FAT/SAT, exportable reports.

For teams that need to validate now. Reliable data, quick decisions.

OUR SERVICES

COMMISSIONING

Unpacking and installation with order conformity check. Connection to customer utilities according to manufacturer specifications. Commissioning and on-site training provided by Blanc Labo technicians.

AFTER-SALES SERVICE

Preventive and corrective maintenance with customised plans: original spare parts, on-site interventions and remote assistance. Options for contracts, SLAs and scheduled downtime calendars.

CONSUMABLES, SPARE-PARTS

Agile supply of consumables and wear parts: identification of references, quick quotation and scheduled delivery according to your usage plan.